Custom industrial parts China manufacturer & supplier

Manufacturing custom parts for Europe & USA over 15 years, Providing customized processing services for various metal & plastic parts, rapid proofing and small batch production are also our strengths.

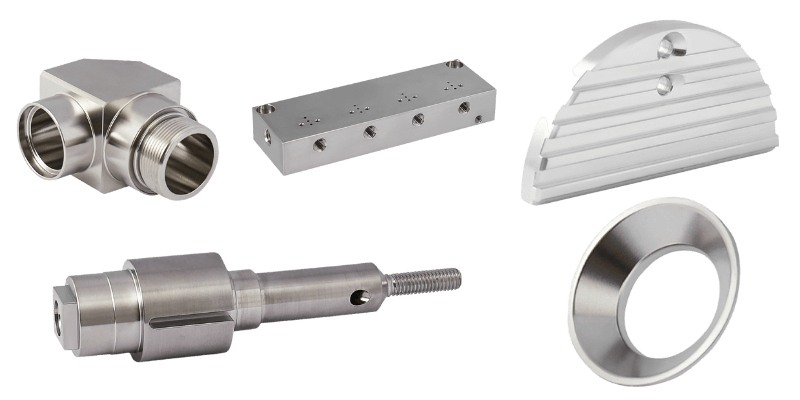

Our Products

At Ebufun Tech, we specialize in crafting custom machinery components that meet the highest standards of precision and durability.

CNC Machining

CNC Machining for custom parts in various industries like machinery, automotve, aviation, medical and robot, materials carbon steel, stainless steel, aluminium, titanium and plastic, rapid prototyping and small volume production in 2 days.

Sheet metal fabrication

Sheet Metal Fabrication of metal components for Electronic enclosure & parts, automotive parts, chassis and brackets, made of carbon steel, stainless steel, brass and aluminium by Laser Cutting or stamping. Welcome quick sampling and small-batch production.

3D Printing

3D Printing for custom parts rapid prototyping and small quantity production in as fast as 1 day, material plastic and metal.

Tooling Molding

Customized tooling or molding for plastic injection and on-demand production. Provide mold tooling design and production as requirements.

About Ebufun

Over 15 years exporting experience to Europe and USA, Ebufun Tech provides custom parts for packaging, automotive, aeroplane, medical and robot industries. Our business philosophy is Customer first, Quality is life.

Why Choose Us

Our professional and experienced team can offer high quality and fast production.

Customized, small quantity accepted

ISO standard quality management and after-sale warranty

Samples completed in 3 days, punctual delivery

Excellent supply chain and efficient production to control costs

Company Advantages

Customized Processing, Rapid production, Quality Guarantee, Competitive Price, Small-batch accepted, Free Sample.

Fulfill custom and low-volume production, Rapid production and delivery, Quality Warranty and After-sale Service, Competitive Pricing

Our Solution

Needs Assessment

Engage in in-depth communication with the client to understand their specific needs, including the intended use of the product, expected functions, size specifications, etc.

Design Review

Collect the client's design files and have our team of engineers review them to ensure manufacturability.

Material Selection

Recommend suitable metal materials and surface treatment methods based on the application and performance requirements of the product.

Rapid Prototyping

Utilize advanced manufacturing technologies such as CNC machining and 3D printing to produce prototypes quickly.

Quality Inspection

After prototyping, conduct strict quality checks to ensure the sample meets the design requirements.

Feedback and Iteration

Send the prototype to the client for evaluation and make necessary adjustments and optimizations based on their feedback.

Design Optimization

Work closely with customers and the design team to ensure that the design meets functional and aesthetic requirements while also considering manufacturability and cost-effectiveness. Use simulation software for pre-design analysis to predict potential issues and resolve them in advance.

Optimal Manufacturing Process

Select the most suitable manufacturing process based on the material, structure, and functional requirements of the product. This may include traditional machining, laser cutting, or modern 3D printing technologies.

Cost Assessment

Conduct a detailed analysis of the costs involved in each production step, including materials, labor, transportation, and time costs. Reduce unnecessary expenses by optimizing design and process flow to ensure competitive pricing of the product.

Supply Chain Management

Establish a strong supplier network to ensure the quality and supply stability of raw materials and components. Optimize inventory management to reduce inventory costs and the risk of excess.

Rapid Production

Use automated and semi-automated production equipment to shorten the production cycle. Implement a rapid response mechanism for urgent orders to complete production as quickly as possible.

Quality Control

Implement strict quality monitoring during the production process to ensure that each product meets international standards and customer requirements. Perform additional inspections and tests for critical stages.

Continuous Improvement

Collect customer feedback and market data to continuously improve products and production processes. Implement lean production and Six Sigma methods to enhance efficiency and quality.

✔ Through these steps, we can provide customers with efficient and flexible small-batch production services, helping their new products quickly enter the market while maintaining high quality and cost-effectiveness. If you need further assistance or have any questions, please feel free to contact us.